Computer simulation development of Sumitomo rubber industry with a history of more than 20 years

When did tire development using the computer simulation of Sumitomo Rubber Industry begin? Mr. Nakase: the development of tires simulated by our company has a history of 20 years. In 1992, I introduced supercomputers. Before that, the tire was analyzed by FEM (finite element method), and the damage and deformation of the structure were measured.

Make up the main components of the tire. Sumitomo rubber industry is simulating all of this.

What was the tire product that was originally made using computer simulation? Nakase Gu: the first product was "LE MANS LM701", which was put into production in the autumn of 1997 as a product in 1998. LM701 is the first generation of digital tire, using computer simulation, that is, DRS (digital rolling simulation).

住友ゴム工業のタイヤシミュレーションの歴史<1990年代初めにスーパーコンピュータを社内に導入しましたが、ご存じのように当時のスパコンのレベルは、現在のパソコンの計算能力にも遠く及びません。そのため、最初は簡単な計算だけをやっていました。DRS製品として発表できたのが1997年になったのは、製品開発のために必要な計算に時間がかかったということです。

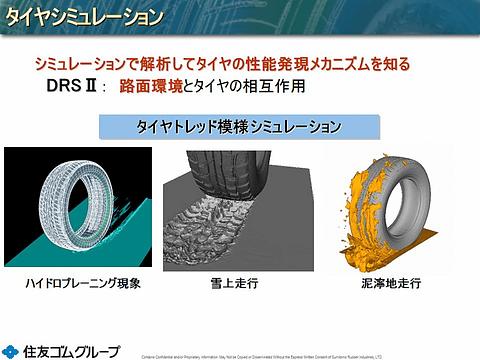

DRSの概要

What happened to the tire monomer simulated DRS in the second-generation DRS II of digital tires? Mr. Nakase: he became the second generation of DRS in the early 2000s. In DRS II, the evaluation so far is very difficult, such as the simulation of driving on rainy days.

Overview of DRS II

<3種類、4種類タイヤを作った場合、「あ、これよかったね。これはどうだったね」となって、それなりのノウハウも残っていきますが、本当のタイヤのメカニズムは分からないまま製品開発が進んでしまいます。

Digital tires have developed from DRS II to DRS III. What is the evolution point of this DRS III? Mr. Nakase: after the tire and road simulation, DRS III began to carry out sound simulation, that is, air simulation.

-- did the tire simulation of Sumitomo Rubber Industry see a completion in DRS III? After that, the simulation of Sumitomo rubber industry seems to be in the process of material, that is, micro-level simulation. Mr. Nakase: one of the reasons for starting to simulate materials is the development of low fuel consumption tires. The so-called low fuel consumption is to reduce energy loss. At that time, not only rubber (compounds), but also tread patterns were very effective. This is to disperse the energy well and avoid the tire twisting concentrated in one place. As a result, in recent tires, the number of tires with straight lines as the main pattern has increased, while the number of tires with elegant curve beauty has decreased.

With the goal of developing tires that meet all elements, the structure of rubber for tires simulates the motion of silicon dioxide and polymers.

Simulation with MD

MD Simulation based on Beijing

Molecular simulation model. Reproduce the actual state of silica as accurately as possible (the whole sphere is silica)

Sumitomo Rubber Industry uses Kyoto's industrial utilization framework and is committed to a new analysis.

![ASCII.jp New iPhone SE and M1 ULTRA [M1 ULTRA] showing the strength of Apple from another aspect](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/28/be7a8975c4e4d655f2fc444f22ef4e97_0.jpeg)

![[Breakthrough infection report] 40.3% answered that they felt that the vaccine was “ineffective”](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/28/f9869be7ca5094f3e2ff937deaf76373_0.jpeg)